Did you know that approximately 95% of all products in North America are shipped in corrugated cardboard containers?

In fact, corrugated boxes are such an essential part of our supply chain, that packaging manufacturers were able to continue operations through the COVID shutdowns as essential business entities.

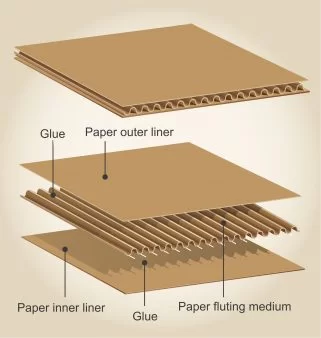

Corrugated cardboard is very durable by design and consists of multiple layers: an outside liner, an inside liner, and a fluted layer between the two. The three layers are glued together to create corrugated cardboard.

Also referred to as corrugated fiberboard, the material offers significant advantages over other options when it comes to shipping.

The Advantages of Corrugated Cartons for Shipping

Plain and simple, corrugated cardboard boxes provide the right level of protection for goods in transit.

Shipping cartons can go through a lot from the warehouse to their final destination. Corrugated packages are designed to survive bad weather, bumpy roads, sudden temperature changes, or rough handling–all while keeping products safely intact.

While no corrugated package is completely indestructible, the materials and makeup of these containers are more likely to protect your products in transit.

Your customers are more likely to be pleased when products arrive in top condition. If customers receive a damaged or broken item, they will be unsatisfied. And we all know that unsatisfied customers are less likely to make a repeat purchase.

Even though corrugated cardboard packaging is very sturdy, it is also lightweight. This can help keep shipping costs down.

Corrugated boxes can be fashioned into a variety of shapes, allowing your company more control over the kind of unboxing experience your consumers will have when your products arrive. This is especially important for e-commerce businesses that ship consumer goods.

And finally, corrugated cardboard boxes are constructed of renewably-sourced materials. Since they are made mostly from trees, a renewable resource, this kind of packaging is very easy to recycle. When recycled properly, corrugated cardboard packaging is processed into paper products and even new boxes.

What’s also great about corrugated cardboard is its multi-use properties. Thanks to the material’s durability, many corrugated packages can be reused multiple times before they even hit the recycle bin.

The sustainability of corrugated cardboard is also what makes this material very affordable.

Choosing the Right Corrugated Cardboard for Your Shipping Needs

When you need industrial packaging, you are often shipping products that are oddly shaped or fragile. What’s great about corrugated packaging is the level of customization available to meet a variety of shipping needs and challenges.

Corrugated cardboard packaging design will depend on your product’s attributes and shipping needs.

Fortunately, the versatility of cardboard corrugated packaging makes it appropriate for multiple industries.

Corrugated cardboard containers can be designed to ship fresh produce and other food goods, automotive parts, or even heavy medical equipment. Almost every industry that ships products will have a need for corrugated cardboard at some point.

There are several features that can be adjusted when engineering a corrugated cardboard package.

Select a Flute Profile

Those arch shaped flutes in the middle layer of a corrugated board are available in different flute profiles, typically rated as A, B, C, E, or F.

A flute provides the thickest profile, and is ideal if you are shipping a product that needs extra cushioning. It also gives cartons extra strength for stacking purposes.

B flute was designed to pack canned goods, and is the preference for high-speed, automatic packing lines.

The most commonly used flute size is C, and is typically used for packing furniture, glass, and other heavy, yet fragile goods. It is actually thicker than the B flute profile.

E and F flutes are the least durable, but have many applications for retail because they provide a surface that is suitable for printing.

Choose the Board Type

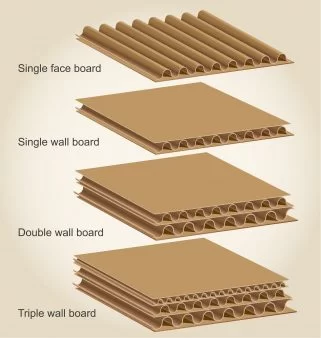

You then have four options for the type of board to be used in your corrugated packaging.

Single-face board is when only one sheet of liner is attached to the corrugated layer. It’s available in rolls and wrapped around products for extra cushioning.

Single-wall is the most standard option. This consists of a single layer of corrugated medium sandwiched between two liner sheets. Boxes with single-wall board are what you typically receive consumer products and goods in.

To make a box more durable, you can add extra liners and layers of the corrugated medium. Two sheets of corrugated medium and three sheets of liner create a double-wall board. A triple-wall board is created with three layers of corrugated medium between four liner sheets, making it the strongest of all the options. This is typically used to ship industrial parts or heavy consumer goods.

Determine the Appropriate Board Grade

Now that you’ve selected these corrugated cardboard specifications, you can choose the board grade that will suit your needs.

If you need your corrugated cardboard box to hold up to stacking pressure, you will want to choose ECT board. ECT stands for Edge Crush Test, a measure of how much stacking pressure a box can take before collapsing.

The chosen flute profile will influence the ECT measurement of your material. This value starts at 23ECT for a single wall, to 120ECT for a triple-wall. The higher the ECT value, the more your corrugated package can withstand. This kind of board is best when you are stacking your boxes on top of each other, such as when they are in a warehouse or on a pallet.

For applications in which you need your box to resist punctures from internal contents or external factors, choose Mullen board. Boards with a higher Mullen value can withstand more pressure before being damaged.

Pick the Right Shape and Size

Corrugated cardboard boxes come in a number of shapes and sizes. From regular slotted, squared-shaped containers, to full telescope designs for fragile items, there are a variety of styles to choose from. You can even select a one-piece design, often referred to as a One Piece Folder (OPF). This is especially great when you want an unbroken printing area for graphics.

Need Expert Advice Before Deciding?

Not exactly sure what corrugated cardboard specifications will fit your specific needs?

Are you trying to decide the ideal shape for your corrugated container?

With so many different options available for corrugated packaging, you may not be sure what to choose for your unique product line.

Consult a corrugated packaging expert that can help you make the right packaging choice to suit your product and shipping needs.

Expert advice from packaging engineers can help you select corrugated cardboard packaging that ensures your shipments arrive in excellent condition.